MEDIA INFO

Know-where:

Bone Structure Reveals Optimal Position for Screws in Fractures

A new model from the Karl Landsteiner University of Health Sciences provides the basis for optimal positioning of orthopaedic screws.

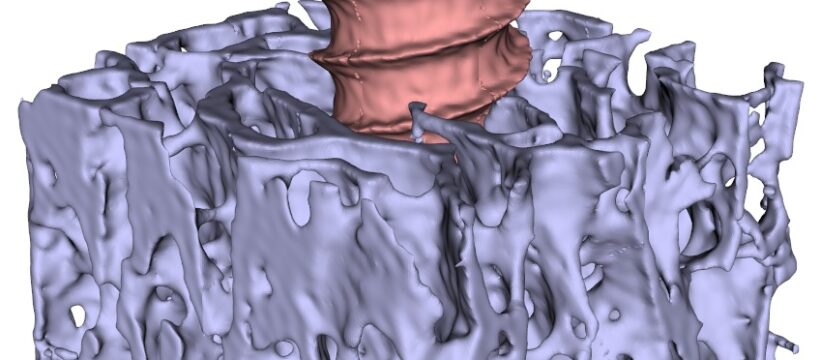

Krems, Austria, 3 June 2025 – Metal screws are indispensable in bone surgery, but they can fail under everyday stress. Now, a new study shows that the risk of failure can be predicted before implantation based on detailed measurements of bone structure. Using high-resolution micro-CT scans, a team of researchers analysed 100 bone samples under ten different load scenarios and identified two key factors that explain up to 90% of the variation in stability. The study, led by Karl Landsteiner University of Health Sciences (KL Krems), thus provides a model for numerous orthopaedic procedures, allowing screws to be implanted more reliably and helping to avoid subsequent complications.

Orthopaedic screws stabilise fractures and ensure proper cohesion of bone fragments. Despite their key role, complications can occur when screws loosen or even break. Until now, it has been difficult to accurately predict this risk because testing methods have not been able to simulate the real stresses in the body. A team from the Division of Biomechanics at the Department of Anatomy and Biomechanics at KL Krems, has now made a decisive contribution to closing this gap by combining state-of-the-art imaging with mechanical stress tests. This enabled them to decipher the interplay between bone structure and screw stability.

Bones Reveal Their Secret

“We wanted to know if it is possible to predict, even before a screw is implanted, whether it will fail under the forces that are to be expected later,” explains Ass.-Prof. DI Dr. Andreas Reisinger, Head of the Division Biomechanics at the KL Krems. “And our answer is yes – and with astonishing precision.” Using a micro-computed tomography (CT) scanner in the Bone Laboratory of KL Krems, the team first analysed the bone structures around the planned implant sites. After implantation the screws were subjected to load tests simulating everyday movements such as walking or lifting. The result: bones with higher volume and denser structure provide significantly more support for the screws – regardless of the type of load.

A total of 100 samples of pig bones – which are very similar to human bones – were tested. The screws were subjected to ten different loading scenarios, including axial (tension and compression), shear, and mixed loading. Six bone parameters were measured. Among these, bone volume (BV) and bone volume fraction (BV/TV – the ratio of bone tissue to total tissue in the tested area) proved to be reliable predictors of the force at which a screw would fail.

Reliable Predictions

Using data from the micro-CT images and the measured failure forces of the screws, the team developed two statistical computer prediction models: one based on bone volume alone, and the other combining several bone parameters in a stepwise approach. Both models demonstrated impressive predictive power. “In all scenarios, we measured the amount of force required for the implanted screws to fail,” explains Prof. Reisinger. “This, of course, varied greatly from sample to sample. And we were able to explain 70 – 90% of this variance with our models. This is a very clear confirmation of our calculations, which now allow us to make predictions.” In fact, surgeons could use this information to identify the most stable screw positions in the bone and reduce the risk of later loosening or fracture.

The results of the study at KL Krems open up new perspectives for personalised orthopaedics. Especially for older people or patients with osteoporosis, more precise predictions can lead to safer and more effective fixation of damaged bones. The work at KL Krems underlines the value of combining engineering and medicine – and how modern prediction models can help improve treatment outcomes.

Image available on request.

Original publication: Silva-Henao JD, Pahr DH, Reisinger AG: Predicting osteosynthesis screw failure by peri-implant bone morphology in multiple loading conditions. J Mech Behav Biomed Mater. 2025;168:107043. doi:10.1016/j.jmbbm.2025.107043. Predicting osteosynthesis screw failure by peri-implant bone morphology in multiple loading conditions – Karl Landsteiner Privatuniversität für Gesundheitswissenschaften

Karl Landsteiner University of Health Sciences (06/2025)

The Karl Landsteiner University of Health Sciences (KL Krems) is an educational and research institution on the Campus Krems and recognised throughout Europe. KL Krems offers modern, demand-oriented education and continuing education in medicine and psychology as well as a PhD programme in Mental Health and Neuroscience. The flexible educational programme is tailored to the needs of students, the requirements of the labour market and the challenges of science. The three university hospitals in Krems, St. Pölten and Tulln and the MedAustron Ion Therapy and Research Centre in Wiener Neustadt guarantee clinical teaching and research of the highest quality. In its research, KL Krems focuses on interdisciplinary fields with high relevance to health policy – including biomechanics, molecular oncology, mental health and neuroscience as well as the topic of water quality and the associated health aspects. KL Krems was founded in 2013 and accredited by the Austrian Agency for Quality Assurance and Accreditation (AQ Austria).

| Scientific Contact Prof. DI Dr. Andreas Reisinger Karl Landsteiner University of Health Sciences Department of Anatomy and Biomechanics Division Biomechanics Dr.-Karl-Dorrek-Straße 30 3500 Krems / Austria T +43 2732 72090 331 E andreas.reisinger@kl.ac.at | Karl Landsteiner University of Health Sciences Mag. Selma Vrazalica, BA Communication, PR & Marketing Dr.-Karl-Dorrek-Straße 30 3500 Krems / Austria T +43 2732 72090 237 M +43 664 883 99 603 | Copy Editing & Distribution PR&D – Public Relations for Research & Education Dr. Barbara Bauder-Jelitto Kollersteig 68 3400 Klosterneuburg / Austria M +43 664 1576 350 E bauder@prd.at L https://www.linkedin.com/company/prd-public-relations-für-forschung-bildung |